Quality Production Engineer

About Hirschmann Automotive

Hirschmann Automotive has been a development and production partner for electromechanical assemblies and components in the automotive industry for over 60 years. The company’s products are used by all major automotive brands worldwide and cover all types of drives available on the market. Do you want to be part of this success story and help shape the future of the automotive industry?

职位描述

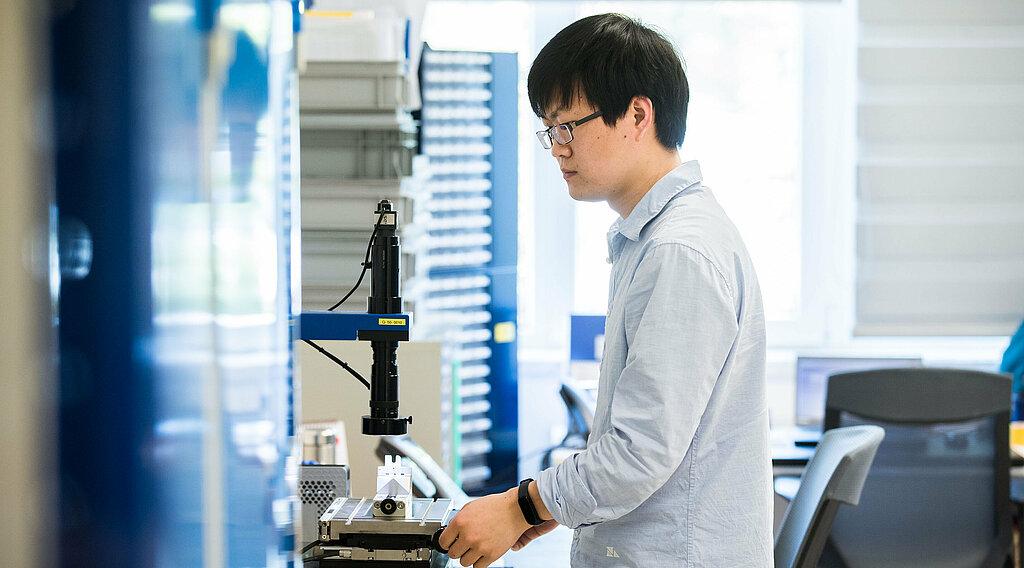

Quality is synonymous with precision and reliability within the company. The integrated management system (IMS) ensures flawless product quality with advanced measurement technology and a state-of-the-art laboratory. As an interface to product-related areas such as product and process development, the team works closely with other departments to ensure quality at every stage of product development.

We are looking for quality-conscious talents who would like to contribute to continuously improving our quality processes with analytical thinking.

#SkillCheck

- Analytical skills - problem solving

- Orientation towards continuous improvement

- Team spirit with good communication skills

- Customer and results orientation

- Good organizational skills

#ChallengeCheck

- Follow up and audit the production department for non-conformances and participate in the closing cycle of corrective actions.

- Providing support to the production department in the analysis of non-value adding processes (Return Material Authorization, remediation, scrap, sorting costs) with the aim of minimizing losses.

- Ensuring that all members of the segment to which he/she belongs are aware of the customer's requirements and expectations regarding quality so that they are met in all areas of activity.

- Continuous collection of quality assurance specific information (defect evolution and analysis, test parameters, test equipment performance, quality assurance data) to ensure compliance with customer quality requirements and internal procedures specifications.

- Training operators on quality issues in the production lines / segment where they operate through specific trainings so that each operator is trained and knows everything that is necessary to perform their work correctly.

- Monitoring the quality trend by drawing up monthly reports (internal PPM, number and evolution of internal defects, cost of rejects) and transmitting the information to the team members to take corrective measures in order to fulfill the objectives of internal PPM and cost of non quality.

#Benefits

- Free transportation

- Meal tickets

- Bank Holidays gift tickets

- Annual performance bonus

- 13th salary

- Medical subscription

- Loyalty bonus

- Opportunities for professional development

- Gym discount